OMTech 50 Watt CO2 Laser

Got my new OMTech 50 Watt Laser today.

I also own 2 Ortur Laser Master 2 – 20 watt diode lasers and a K40 Laser also from OMTech. NOTE: I sold both the K40 and the Ortur LM2’s

After tons of research I have decided that your best bet on buying a Chinese laser system is to buy it from OMTech. Your mileage may vary and in fact some people’s mileage DOES vary. That has NOT been my experience.

The K40 I bought from them and now this 50 watt machine………JUST WORKS. Right out of the box. No damage. Not one scratch. Not one dent. The machines both came aligned right out of the box.

Shipping was fast, the price was competitive albeit you could save a few dollars by buying from other dealers. I don’t recommend it unless you are prepared to take a machine out of the box and spend time aligning it and making it right. If you posses those skills then by all means…….save some money. Me. I posses those skills but it isn’t worth $50 or $100 to me to do all that quality assurance and work.

Now. let dig in a little. Just some stuff you need to know up front.

In order to use this machine you need the DSP version of Lightburn…….Well you don’t NEED it, but you want it. I own Lightburn (for G-Code) which costs $40. You’ll need another upgrade license to work with this controller. That costs an additional $40. Not a biggie in my mind.

The laser comes with some software, called RDWorks. However, there’s about zero chance I’m sticking a USB device from China into any computer on my home network. Just download it yourself to be safer. I’m still not installing it because I use Lightburn exclusively.

The reason for the extra $40 cost of Lightburn is the Ruida digital controller. Except this machine doesn’t actually have a Ruida controller. It is actually a Ryxon KT322N which will NOT BE AUTODETECTED by Lightburn. It is easy enough to set up manually though.

Here’s a big gotcha with this (and other) Ruida controllers. Let me preface this first with a little backstory. I set the machine up in Lightburn at 10mm/s and various power settings. 15, 20, 30, percent etc. Every freaking test circle I tried to cut came out EXACTLY THE SAME. Looked like it was only engraving and not cutting. Apparently there is a controller setting called “Start Speed” which is set to, you guessed it, 10mm/s. I then set my speed in Lightburn to 10.1 and VOILA the power settings varied as I would have expected. It started cutting just fine after that.

The next interesting bit to know is that there is no water temperature monitor on this machine. You will either have to add one (easy and cheap) or you will need an external water chiller. You’re going to want a water chiller. Just get one. It’s kind of crazy that a $400 K40 has a power supply temp monitor and a water temperature monitor and a $1700 laser does not. They really want you to use a water chiller but when you get to this laser power range you probably SHOULD use a chiller anyway.

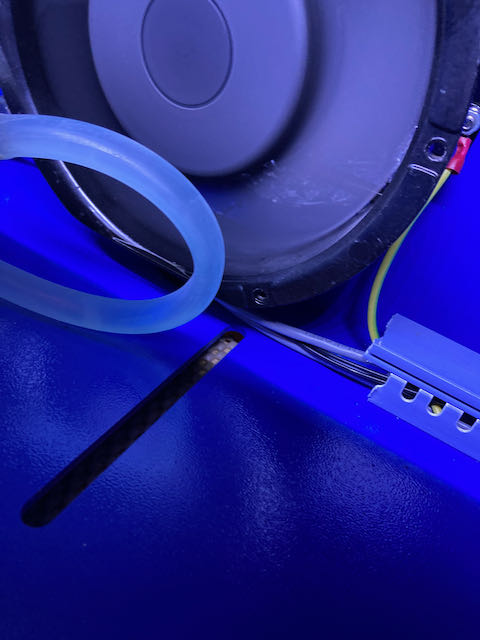

Speaking of water cooling, one thing that kind of scares on this machine is that one run of the water tubing is right next to the unguarded exhaust fan. Yikes.

I will get an adhesive stand off or something and lightly zip tie it so it can’t drift into the spinning fan blades.

One of the main reasons I wanted to upgrade from the K40 was to have better control over the Z axis. This machine has about 8″ of Z axis travel and a manually adjustable bed. Believe it or not I opted for manual adjustment over motorized adjustment on purpose. I prefer to do all the twisting and fiddling myself.

Also I wanted a larger bed than the K40 had. I didn’t need a lot bigger size but I did need to upgrade. I would have loved a 60 watt, or 80 watt or even a larger machine than that but the simple fact was I have limited size and space. My hobby room has a 30″ door frame and also it needed to sit on a 46″ x 24″ workbench that is placed right in front of the window for exhaust. I did all the requisite research and decided that the 50 watt laser was about as big as I can go unless I get a bigger house!

For now I’m keeping the K40 as I’m not done using it. For me it is a valuable learning platform and maybe in the near future I’ll disassemble it 100% and shoot for perfect level and straightness and maybe trick it out with some higher end parts. If you decide to enter the world of laser engraving and cutting I think the K40 is the place to start. For the cost it is the perfect experimentation platform and a good place to learn your craft. And of course its real appeal is in the low cost of the unit and low cost of spare parts such as lenses and mirrors.

Anyway, I’m really happy with this 50 watt laser purchase and OMTech products in general. I’m 2 for 2 as a satisfied customer. I can strongly recommend using them as a purchasing source. I’d be willing to bet most issues with these lasers are related to shipment and poor handling by the shipping companies.

I’m sure as I learn more about the 50 Watt laser I’ll add it here or blog more about it.